Dry Out (Refractory Drying)

MLK Dry Out Energy provides professional and systematic dry out services for structures made with refractory concrete, such as power plants and waste-to-energy plants, where drying is required before commissioning. Our engineers monitor the system 24/7, swiftly intervening in case of any malfunctions or errors, ensuring successful drying processes.

Why Dry Out?

Water is a common material in the mixing of mortars used in assembly. After assembly, water must be removed from the primer's exterior; otherwise, it can cause serious cracks inside by compressing steam. Therefore, the drying of refractory products must be done carefully.

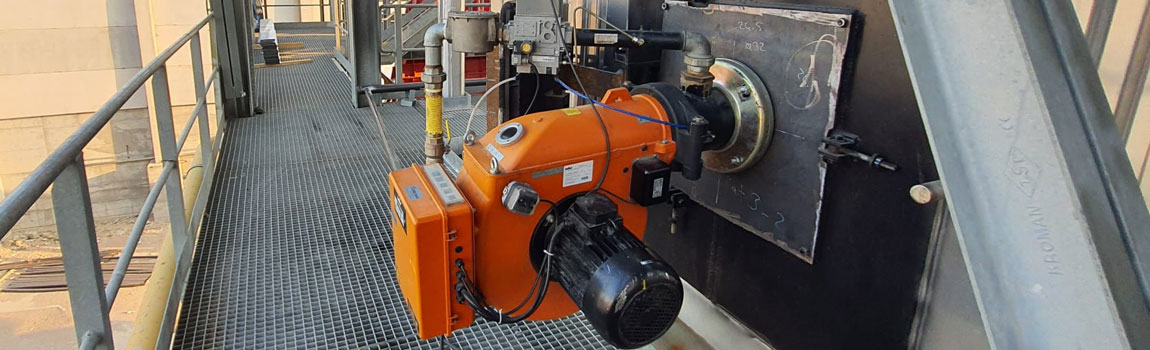

External burners are used to dry the refractory lining. These external burners are mounted on manhole covers and spray flames inward. This gradually increases the internal temperature systematically according to the programs. Thus, the drying process is completed without damaging the refractory.

Main Areas:

- Power Plants

- Recycling Facilities

- Special Facilities

- Metallurgical Industry

- Ceramic Industry

- Cement Industry